Vapor Liquid Separator Design Calculation Xls

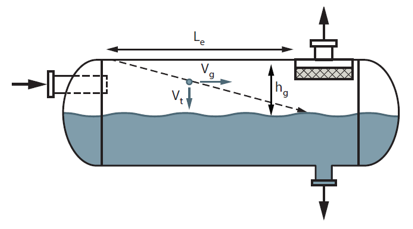

Fabricate and ship this type of separator in skid mounted assemblies and it takes a larger diameter separator for given gas capacity a a horizontathan l vessel.

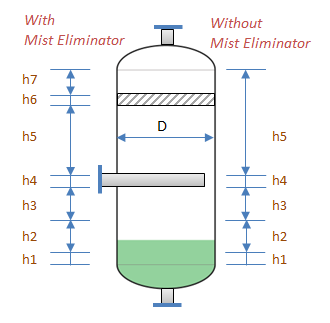

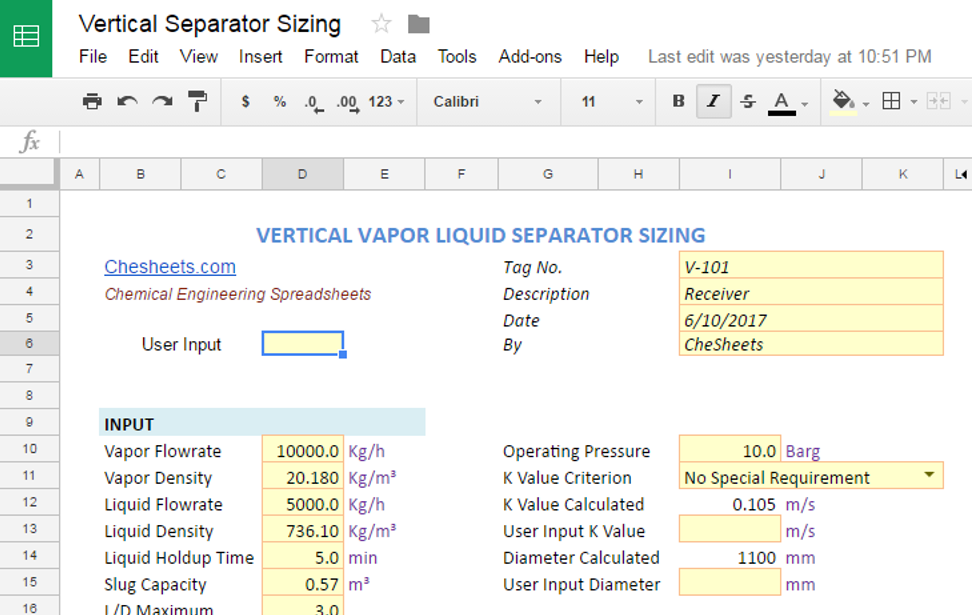

Vapor liquid separator design calculation xls. These two types of process vessels are utilized throughout the chemical process. From this it can be seen that this type of separator is most often used on fluid streams with low gas oil ratios. Vapor liquid vertical separator does the design sizing and calculation for a vertical gas liquid separator with or without mesh pad based on souders brown equation using k values from gpsa droplet size. Project area equipment objectives process data operating pressure operating temperature gas flow rate molecular weight z factor viscosity oil flow rate density water flow rate density 900 psig o 250 f 30 mmscfd 31 47 0 9800 0 8 cp 1000 bopd 3 47 10 lb ft 250 bwpd 3 57 38 lb ft v 300.

Api calculations company location api separator calculations density of the water in g cm3 temp f absolute viscosity kinematic viscosity centipoises centistokes ssu ft sec poise density g cm3 viscosity in poise temperature in deg f design oil droplet in cm terminal velocity in cm s oil droplet size in microns specific gravity. Horizontal separator adequacy check sheet. If it is out of this range new diameter is selected and all above steps are repeated till desired l d ratio is obtained. Horizontal and the vertical gravity separators.

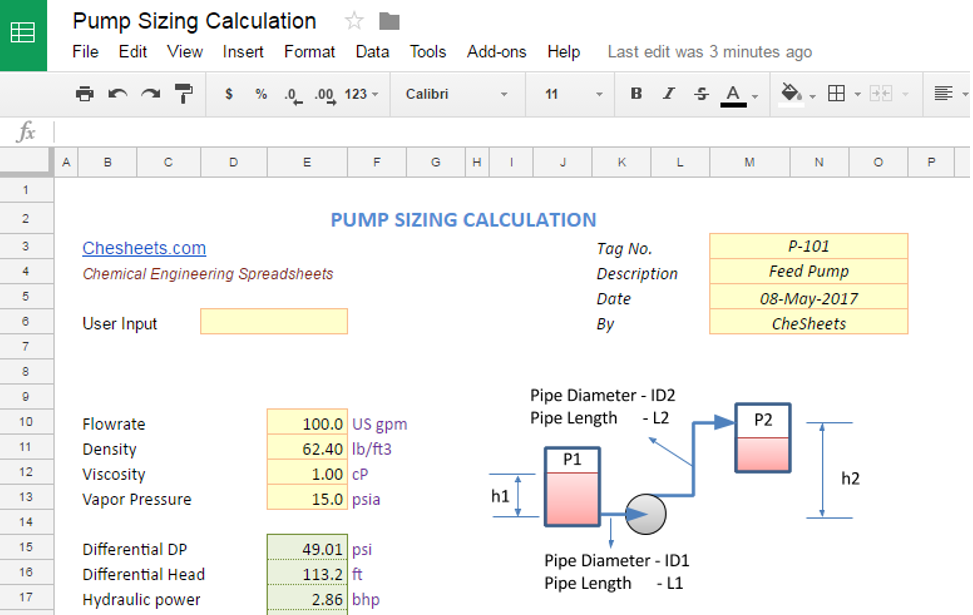

Spreadsheet for design sizing of vapor liquid vertical separator. There are two methods for sizing gas liquid separators. Vapor liquid separators are one of the most common types of process equipment. Pump sizing calculation sun 07 may 2017.

Therefore the souders brown parameter for horizontal separators k sh can be estimated in by equation 4 in terms of k sv read from figure 2 for vertical separator 3. L d ratio is typically kept in the range of 3 to 5. Sizing of the horizontal separators are more complicated. Gas liquid separators sizing parameter in the december 2014 tip of the month totm 1 we discussed troubleshooting of gas liquid separators for removal of liquids from the gas stream leaving the separator.

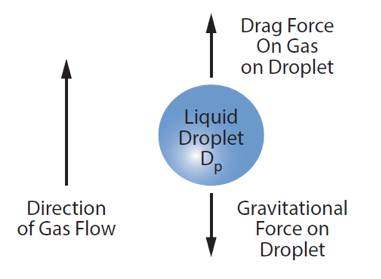

Droplet settling theory method 2. Chemical engineering calculations to assist process plant operation and maintenance engineers. In other words handling considerably more liquid than gas. Calculation for vessel thickness vessel volume and sizing of verticl horizontal separator.

This article provides step by step procedure for two phase vertical vapor liquid separator design. Pump is a most. Background this course provides a step by step development for the design of two types of liquid in gas separation devices.