Z Pin Sprue Puller Design

These connect the main runner to the nozzel of the injection molding machine.

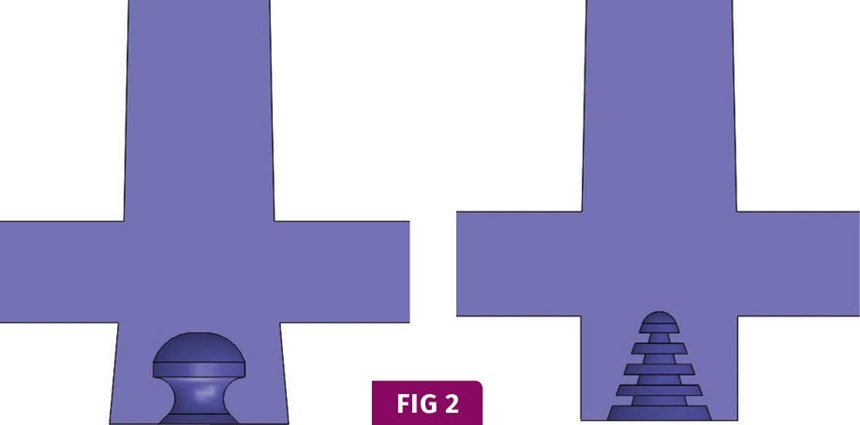

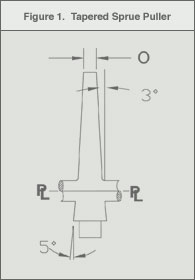

Z pin sprue puller design. Sprue pullers are also required in most two plate molds that use hot sprue bushings or hot runner nozzles unless the hot runner nozzle is a valve gate type. Typically the sprue diameter should be slightly larger than the nozzle diameter. Intelligent cad automates mold design also more aggressive sprue puller pins are sometimes required in order to increase the pulling force. Sprue and sprue puller design.

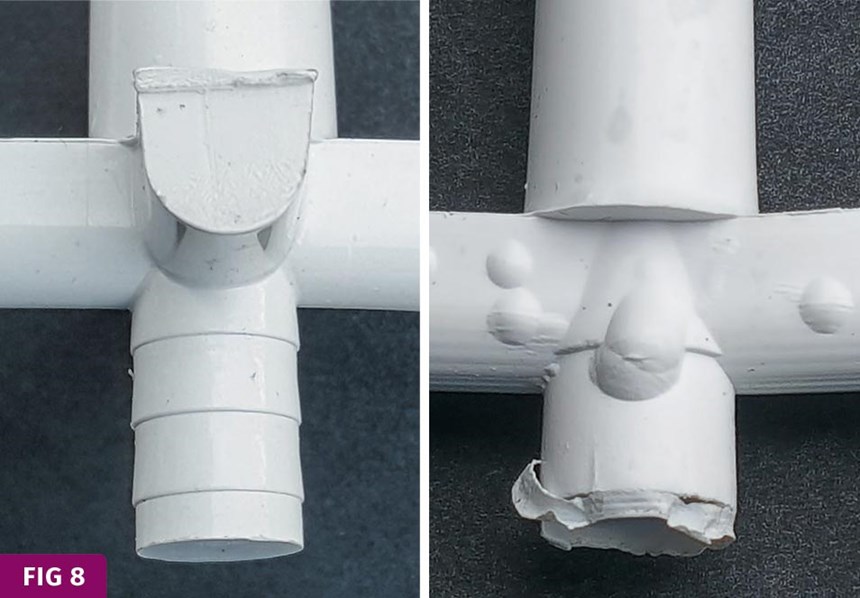

Undercut or z type sprue pullers are satisfactory for all grades. The bushes are smooth in finish and are polished in the drawing direction that ensure the hassel free seperation of bushing with the sprue. The leader pins sprue puller pin stop pins and return pins are configured and positioned on the mold according to information from the vendor. The sprue puller bushings are the special components that are used in molding cycle.

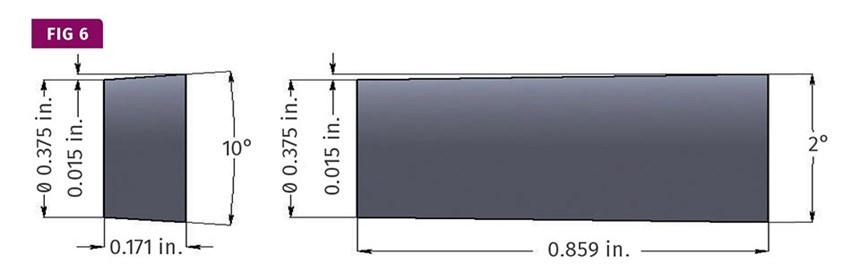

When designing the mold make sure to increase the bearing length of the sprue puller ejector pin in case the pin needs to be shortened to increase the puller s volume. It is typically located directly opposite the shank end of the sprue bushing and its purpose is as the name implies to pull the molded sprue out of its bushing. A sprue puller is one of many design requirements for most two plate cold runner molds in order for it to run fully automatic. Longer sprues may require more taper 3 to 5.

Victor taichung vturn x200 with hydraulic steady rest for shaft turning 20110715 mpg duration. Mold design has great impact on productivity and part quality directly affecting the profitability of the molding operation. The sprue should have sufficient draft from 1 to 3 to minimize drag and sprue sticking.