Vapor Recovery Tower Design

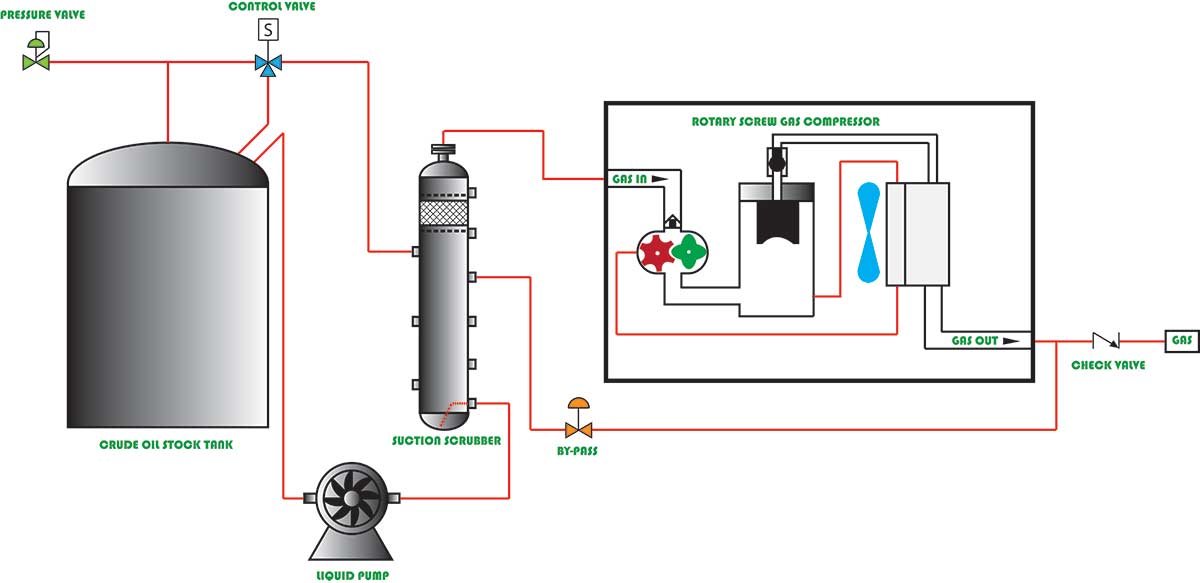

A vapor recovery tower vrt is a tall vertical pressure vessel that is installed between the production separator or treater and the oil storage tanks.

Vapor recovery tower design. Industry leader in vapor recovery innovation. Vapor recovery is a critical process in the establishment of oil production facilities. Vapor recovery tower vrt the hy bon edi vrt provides flash gas recovery at near atmospheric pressure without the potential of oxygen ingress from the top of the storage tanks. Jessco solutions is a leading innovator of vapor recovery solutions for the oil and natural gas industry.

The liquid head pressure is used to move liquids to stock tanks. A vapor recovery tower is a tall pressure vessel which is installed between the production separator s and the liquid storage tanks a vapor recovery tower technically meets the standards of being a pressure vessel and thus is considered by the epa to be process equipment. The vapor recovery tower is a tall pressure vessel or two phase separator installed between low pressure separator or heater treater and storage tanks. Potential to reduce stock tank emissions below epa oooo threshold.

Jessco solutions offers standard vrts. Back to all charts vapor recovery towers typical sizing download xlsx diameter inches height inches volume barrels per day item 1 30 30 20 53527163 1 183 item 2 30 35 24 90447836 1 434 item 3 36 30 29 57079115 1 703 item 4 36 35 35 86244884 2 066 item 5 42 30 40 24913239 1 960 item 6 42 35 48 81277758read more. Non code coded vessels available upon request. It provides for flash gas recovery from the oil at near atmospheric pressure while eliminating the potential for oxygen being introduced into the process from the oil storage tanks.

Vrts should be engineered for proper retention time to allow gas to separate from the liquid. The correct layout makes all the difference in maximizing your tank battery production. Vapor recovery towers vrts are used to prevent oxygen in the flash gas stream. We are committed to producing only the highest quality vapor recovery units and vapor recovery towers at competitive prices.

Let our engineers design a custom layout that will help you. It is not considered to be a. Vapor recovery tower design dcasto chemical 2 feb 12 15 57 if this is a continous operation with more than 10 bbls per day i wouldn t use a vrt i d use a condensate stabilizer or just a heater treater. Design and hosting by.

Vapor recovery tower a vapor recovery tower vrt is a tall pressure container installed between the production separator s and the liquid storage tanks.