Vapor Liquid Separator Design Xls

If it is out of this range new diameter is selected and all above steps are repeated till desired l d ratio is obtained.

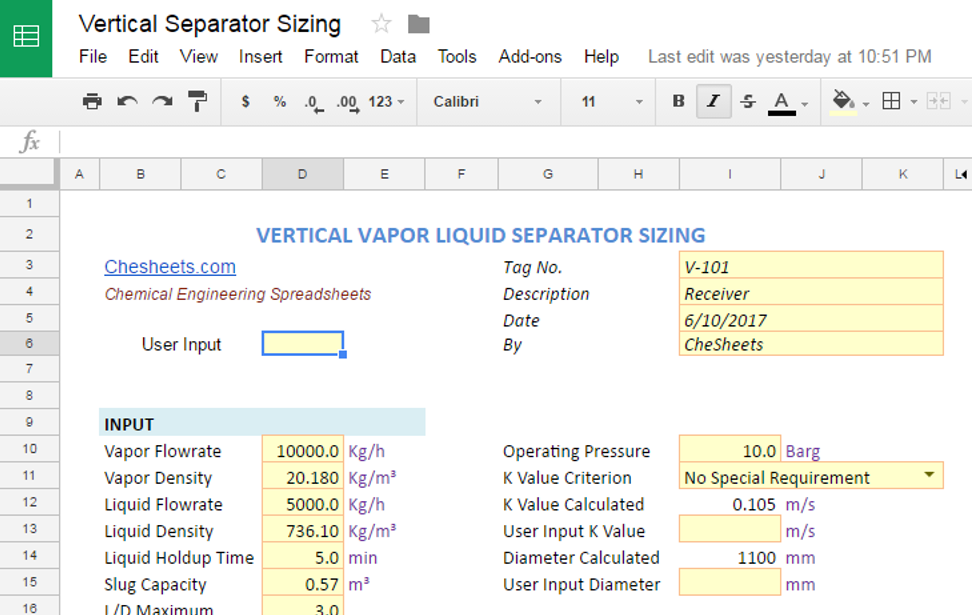

Vapor liquid separator design xls. L d ratio is typically kept in the range of 3 to 5. Droplet settling theory method 2. Vapor liquid horizontal separator does the design sizing and calculation for a vertical gas liquid separator with or without mesh pad based on souders brown equation using k values from gpsa droplet size. Spreadsheet for design sizing of vapor liquid vertical separator.

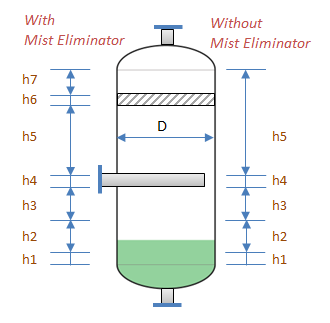

Oil gas separators flash tanks separators. Vapor velocity factor k 1. K could then be determine through a vapor velocity design factor vapor liquid separators at 8 flooding chart. All heights are summed up to calculate overall length of separator.

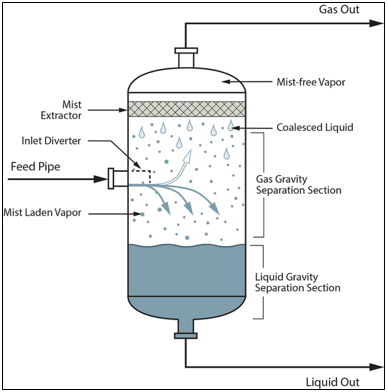

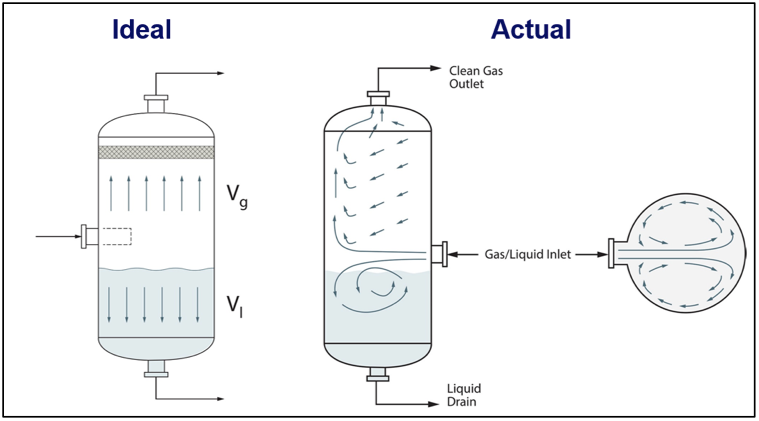

The vertical separator has the advantage that it will handle greater slugs of liquid without carry over to the gas outlet and the action of the liquid level control is not quite as critical. Background this course provides a step by step development for the design of two types of liquid in gas separation devices. Separator with pneumatic controls. Vapor liquid vertical separator does the design sizing and calculation for a vertical gas liquid separator with or without mesh pad based on souders brown equation using k values from gpsa droplet size.

Pump sizing calculation sun 07 may 2017. This term appears in vessel design calculation where souders brown equation is use to obtain vapor liquid separation factor. Due to the greater vertical distance between the liquid level and the gas outlet there is less tendency to re. Horizontal and the vertical gravity separators.

Gas liquid separators can be generally divided into two main groups high gas to liquid ratio e g. Vapor liquid separators are one of the most common types of process equipment. Flare knock out drums scrubbers and low gas to liquid ratio e g. Separator design for liquid removal from gas streams john pietranski p e ph d.

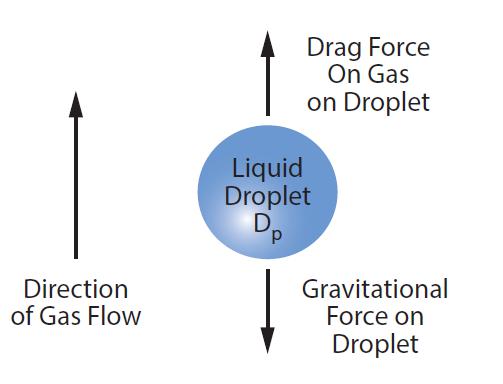

There are two methods for sizing gas liquid separators. This article provides step by step procedure for two phase vertical vapor liquid separator design. These two types of process vessels are utilized throughout the chemical process. Gas liquid separators sizing parameter in the december 2014 tip of the month totm 1 we discussed troubleshooting of gas liquid separators for removal of liquids from the gas stream leaving the separator.

Along with providing storage for liquid a chief function of most vessels used in industrial refrigeration is to separate liquid from vapor to assure that the vapor reaching the compressor is free of significant amounts of liquid. Chemical engineering calculations to assist process plant operation and maintenance engineers. Vapor liquid vertical separator sun 21 may 2017.