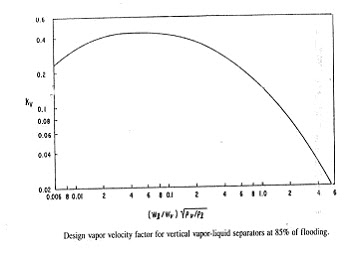

Design Vapor Velocity Factor

Calculate flood velocity u n using following equation.

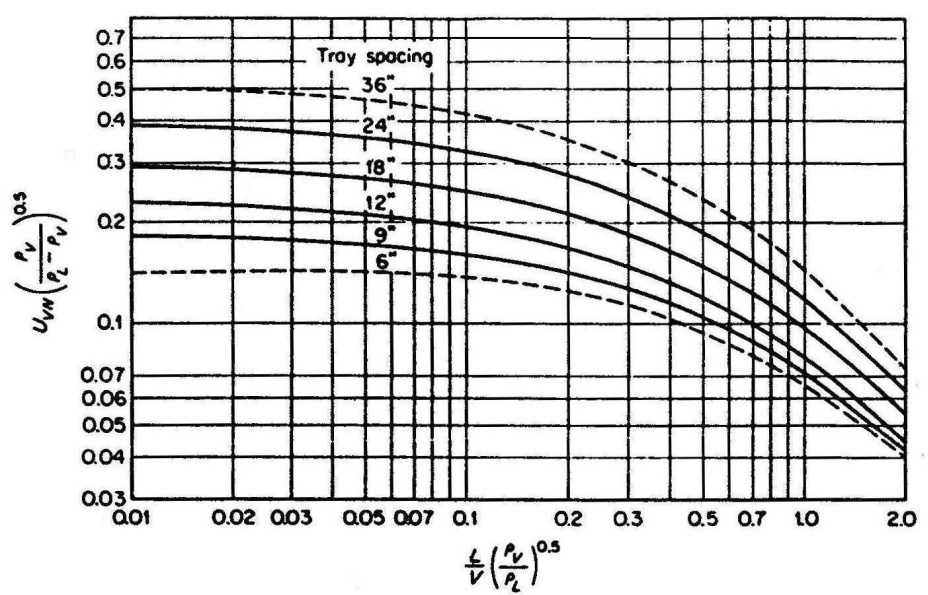

Design vapor velocity factor. This balance yields an expression relating the vapor and liquid densities and a capacity factor c with velocity units to the flooding velocity. A process in which a liquid or vapor mixture of two or more substances is separated into. Vapor velocity factor k 1. Eight practical steps factors affecting operation.

Vapor liquid separation factor which is equal to f l f v p v p l. Comes out to be 0 017. The souders brown equation named after mott souders and george granger brown has been a tool for obtaining the maximum allowable vapor velocity in vapor liquid separation vessels variously called flash drums knockout drums knockout pots compressor suction drums and compressor inlet drums. This term appears in vessel design calculation where souders brown equation is use to obtain vapor liquid separation factor.

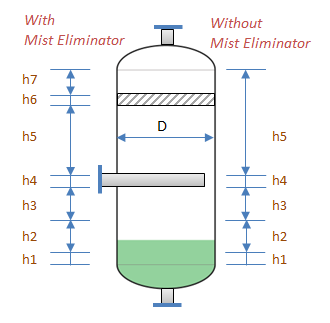

Calculate c factor c sb using following kister and haas correlation. Where q is the vapor volumetric flowrate. This is the velocity of upward vapour at which liquid droplets are suspended. Vapor space the volume of a vapor liquid separator above the liquid level.

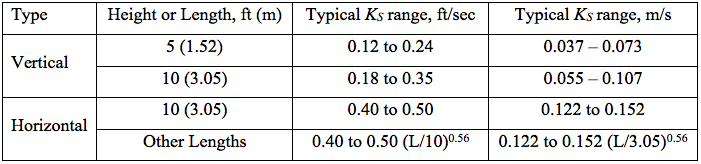

Maximum design vapor velocity is obtained by multiplying the vapor velocity factor with p l p v p l 0 5. A design velocity of 80 to 85 of the flooding velocity is then used. Terminal velocity or drop out velocity the velocity at which a particle or droplet will fall under the action of gravity when drag force just balances gravitational force and the particle or droplet continues to fall at constant velocity. Liquid vapor separators fluids separator fluids separator v sounders brown k rhol rhog source calculates the maximum allowable vapor velocity in a two phase separator to permit separation between entrained droplets and the gas using an empirical k factor named after sounders and brown this is a simplifying expression for terminal velocity and drag on particles.

Downcomer exit velocity 1 5 ft sec. Capacity factors the capacity factor can be determined from theory it depends on droplet diameter drag coefficient etc but is usually obtained from correlations based on experimental data from distillation tray tests. K could then be determine through a vapor velocity design factor vapor liquid separators at 8 flooding chart. Where p is in psig k is in feet sec.

Vessel diameter is calculated based on vapor velocity v. Net area calculation the net area represents smallest area available for vapour flow in the inter tray.