Design Of Vapor Liquid Separator

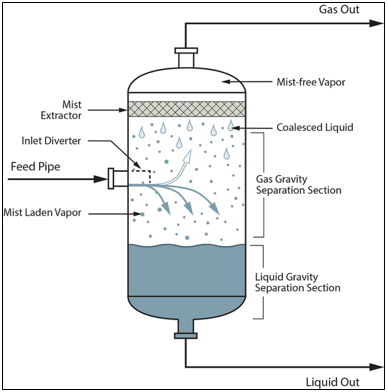

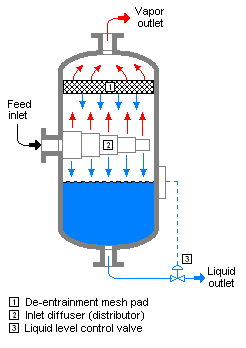

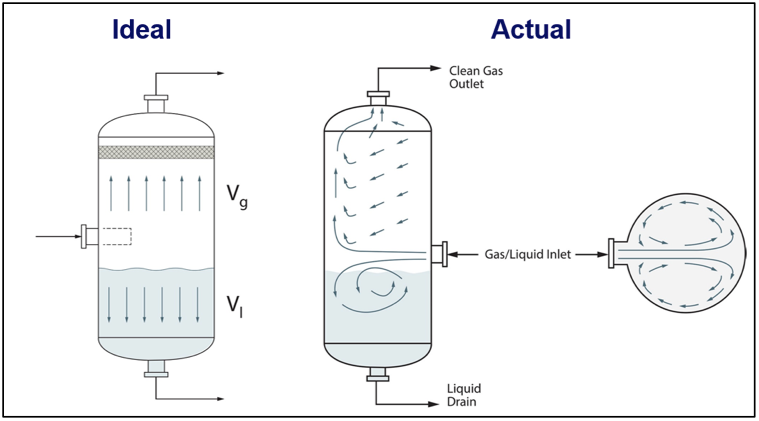

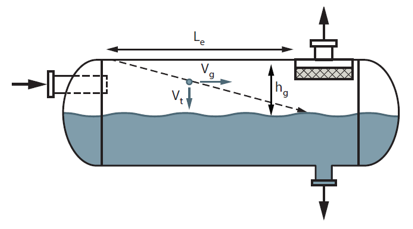

The vapor travels upward at a design velocity which minimizes the entrainment of any liquid droplets in the vapor as it exits the top of the vessel.

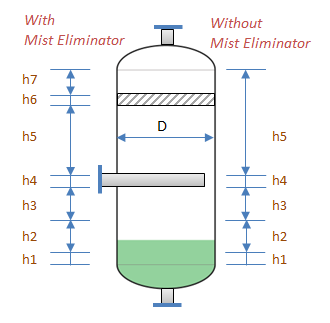

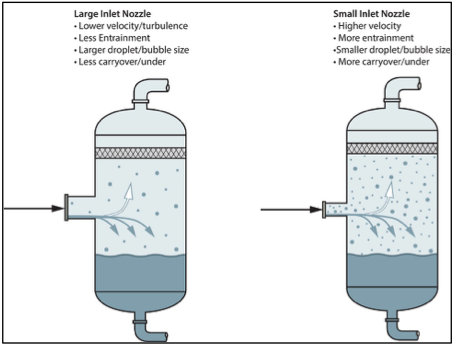

Design of vapor liquid separator. Vapor liquid vertical separator does the design sizing and calculation for a vertical gas liquid separator with or without mesh pad based on souders brown equation using k values from gpsa droplet size. Rated flow scfm separator total volume gallons liquid holding volume gallons shipping weight lbs. Vapor liquid separation occurs in three stages. The vapor travels through the gas outlet at a design velocity which minimises the entrainment of any liquid droplets in the vapor as it exits the vessel.

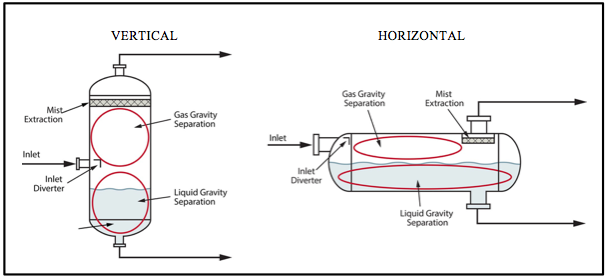

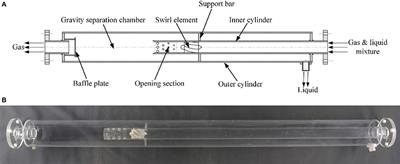

Therefore the souders brown parameter for horizontal separators k sh can be estimated in by equation 4 in terms of k sv read from figure 2 for vertical separator 3. Horizontal vessels have some advantage over verticals for liquid liquid separation due to the larger interface area available in the horizontal style and the shorter distance particles must travel to coalesce. Along with providing storage for liquid a chief function of most vessels used in industrial refrigeration is to separate liquid from vapor to assure that the vapor reaching the compressor is free of significant amounts of liquid. The feed to a vapor liquid separator may also be a liquid that is being partially or totally flashed into a vapor and liquid as it enters the separator.

01 april 2011 conventional gas liquid separator in this standard the term conventional gas liquid separator is referred to vertical or horizontal separators in which gas and liquid are separated by means of gravity settling with or. Vapor liquid separators are one of the most common types of process equipment. Pressure drop for vls series vapor liquid separators vls 320 vls 570 vls 440 vls 100 vls 220 vls 1040 model number inlet outlet connection height in. The size a vapor liquid separator drum or knock out pot or flash drum or compressor suction drum should be dictated by the anticipated flow rate of vapor and liquid from the drum.

This article provides step by step procedure for two phase vertical vapor liquid separator design. Liquid vapor separation vertical vessel. The following principles of design for liquid liquid separation apply equally for horizontal or vertical separators.