Design Of Vapor Absorption System

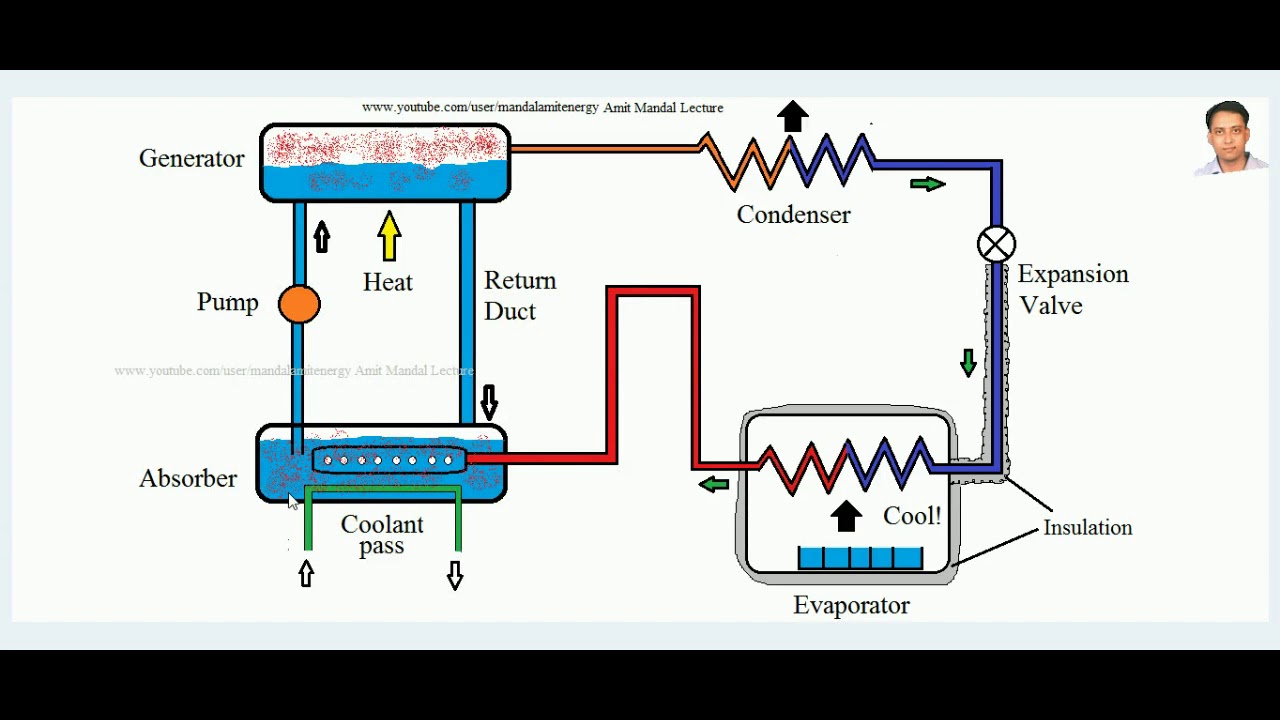

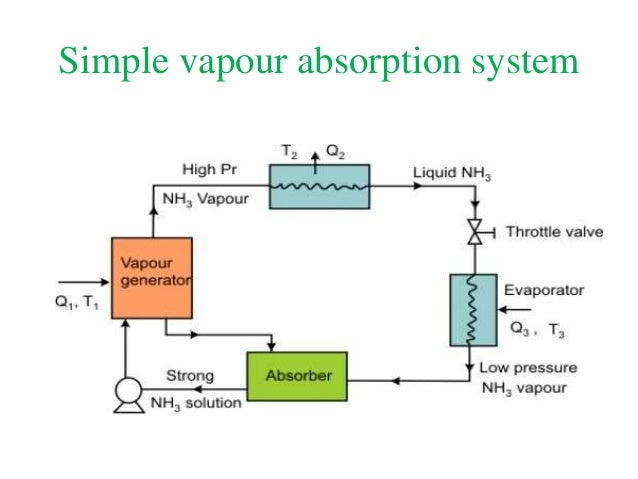

The vapour from the evaporator is allowed to be mixed and absorbed in the absorber.

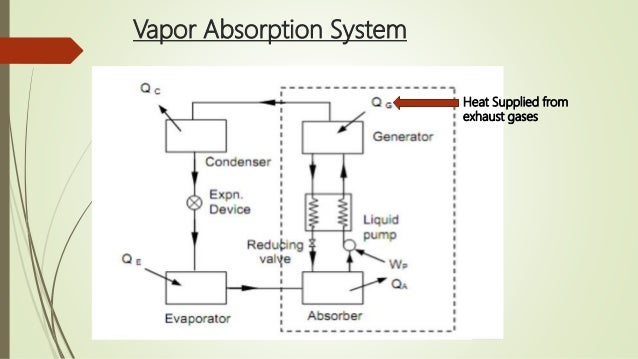

Design of vapor absorption system. In vapor absorption system ammonia is used as the refrigerant which has very high affinity to dissolve in water. Absorber just like the vapor compression refrigeration cycle the absorption machine operates. Absorption system employs heat and a concentrated salt solution lithium bromide to produce chilled water. A breadboard prototype of an absorption system for refrigeration using heat from the exhaust gases is to be designed built and tested.

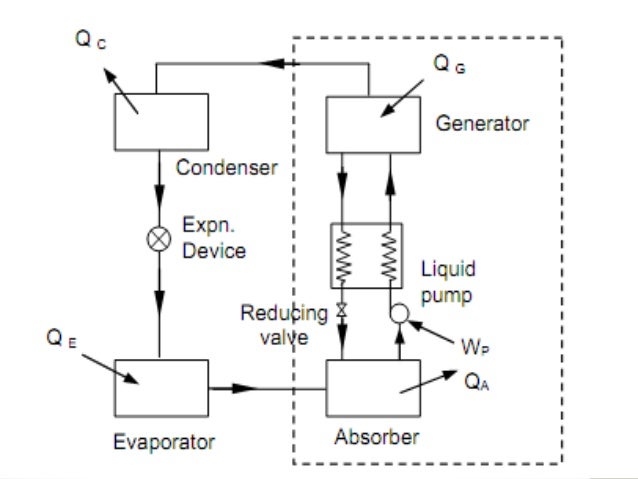

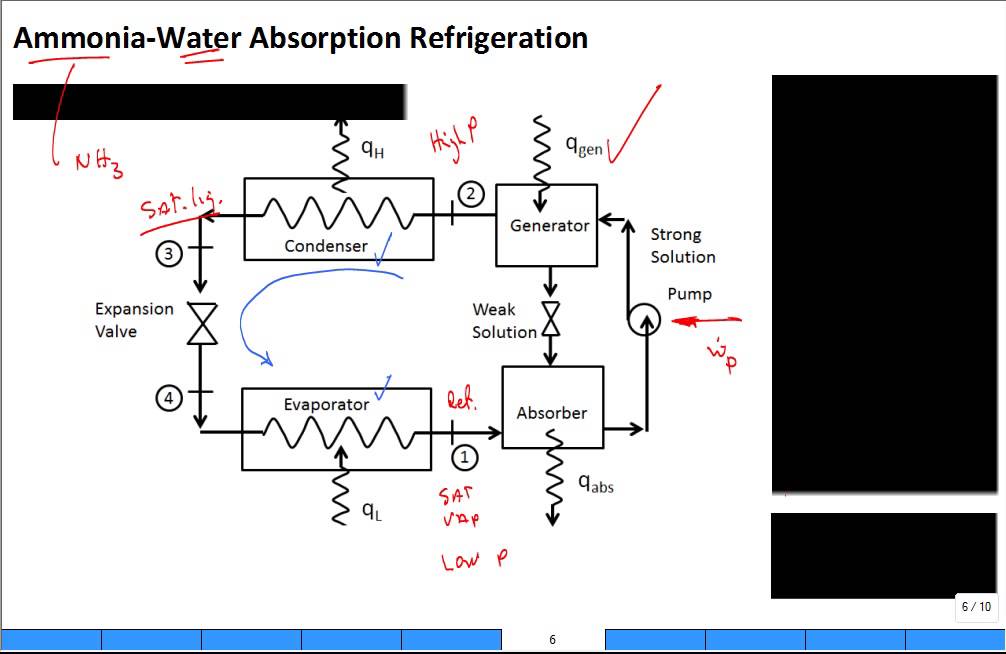

The compressor is replaced by the absorber and the generator in the absorption refrigeration system. The most commonly used fluids in the absorption system are water as absorbent and ammonia as refrigerant. The heat of absorption generated in the process is rejected from the absorber to the circulating cold water in a heat exchanger dipped in the solution contained in the absorber. In the early years of the twentieth century the vapor absorption cycle using water ammonia systems was popular and widely used but after the development of the vapor compression cycle it lost much of its importance because of its low coefficient of performance about one fifth of that of the vapor compression cycle.

The primary aim of the present work is to design an air conditioning system based on vapour absorption cycle that utilizes a renewable energy source for its operation. In its simplest design the absorption machine consists of 4 basic components. In vapor absorption system there is no traditional compressor instead there is absorber. Here are various processes of vapor absorption cycle.

In the vapor absorption system the refrigerant used is ammonia water or lithium bromide. The vapor absorption refrigeration system comprises of all the processes in the vapor compression refrigeration system like compression condensation expansion and evaporation.